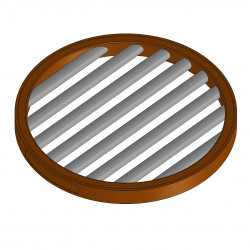

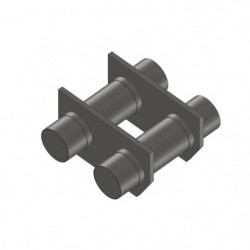

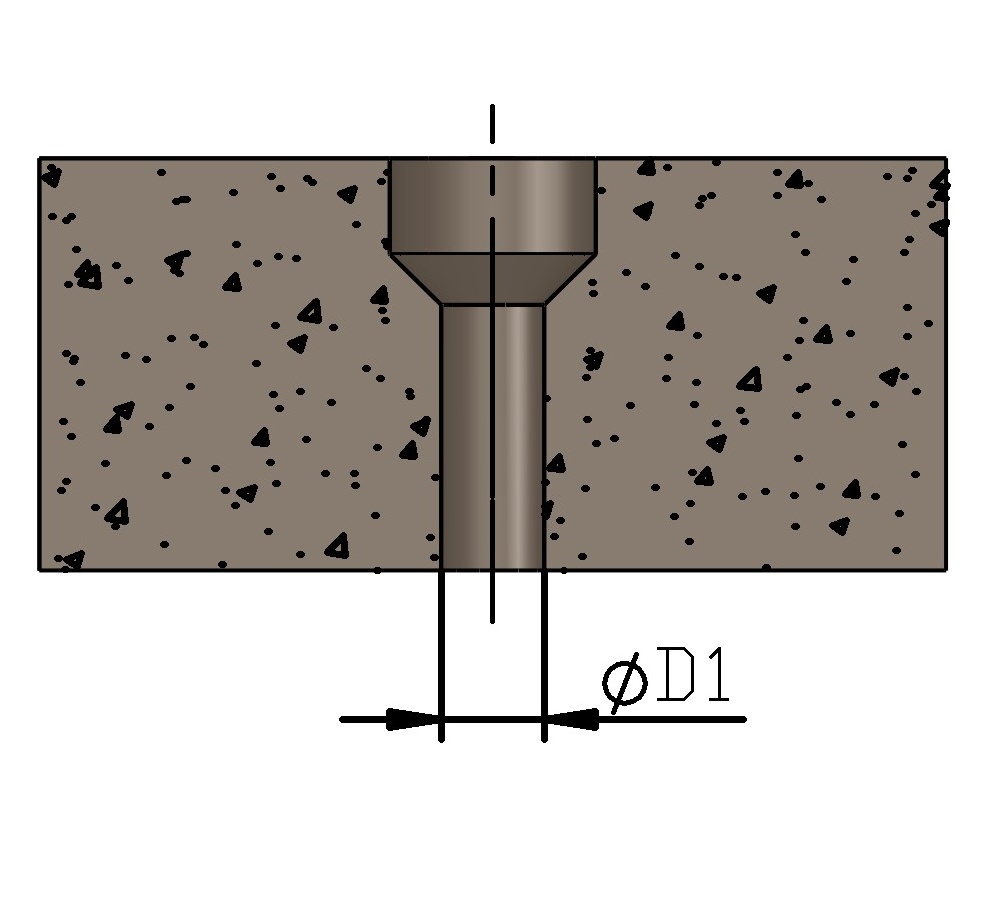

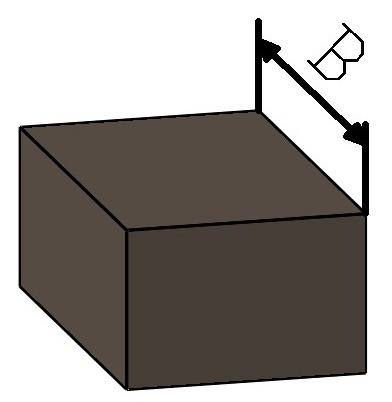

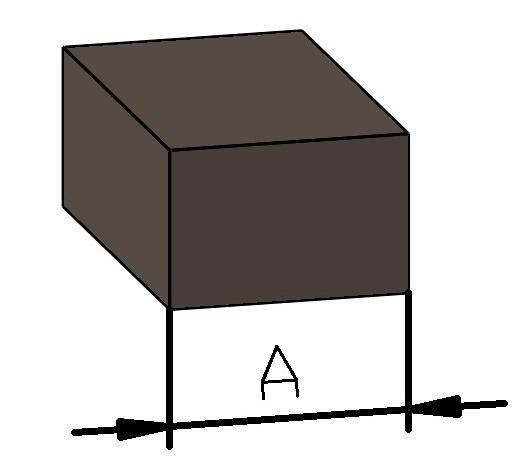

Magnetic grid / finger magnet MR 390x140x50/4 F-P-MODEL1

50568

In Stock

We'll send on Monday

Price

€392.07 / pcTax excluded

Magnetic grid / finger magnet MR 390x140x50/4 F-P-MODEL1

50568

In Stock

We'll send on Monday

Price

€392.07 / pcTax excluded

Magnetic cubes

Magnetic cubes Small magnets

Small magnets Bar magnets

Bar magnets Large magnets

Large magnets Flat magnets

Flat magnets Circular magnets

Circular magnets Eye magnet

Eye magnet Ferrite magnets, cylinders, magnetized in parallel to the axis

Ferrite magnets, cylinders, magnetized in parallel to the axis Ferrite magnets, prisms, magnetized perpendicularly to the surface

Ferrite magnets, prisms, magnetized perpendicularly to the surface Ferrite magnets, rings, magnetized in parallel to the axis

Ferrite magnets, rings, magnetized in parallel to the axis Ferrite magnets, cylindres, magnetized with multiple poles

Ferrite magnets, cylindres, magnetized with multiple poles Color ferrite magnets

Color ferrite magnets Cheap magnets

Cheap magnets SmCo magnets, cylinders, magnetized in parallel to the axis

SmCo magnets, cylinders, magnetized in parallel to the axis SmCo magnets, prisms, magnetized perpendicularly to the surface

SmCo magnets, prisms, magnetized perpendicularly to the surface SmCo magnets, rings, magnetized in parallel to the axis

SmCo magnets, rings, magnetized in parallel to the axis Magnetic letters

Magnetic letters Coloured magnets

Coloured magnets Color conical rare-earth magnets

Color conical rare-earth magnets Color magnetic pegs

Color magnetic pegs Magnets in the plastics cases

Magnets in the plastics cases Magnets in the metal cases

Magnets in the metal cases Magnets in the silicone cases

Magnets in the silicone cases Strong office magnet, neodymium

Strong office magnet, neodymium Magnetic arrows

Magnetic arrows Magnetic numbers

Magnetic numbers Magnetic smileys

Magnetic smileys Magnets for business cards

Magnets for business cards Self-adhesive magnet – a counterpart

Self-adhesive magnet – a counterpart Counterpart for the magnet with a screw hole

Counterpart for the magnet with a screw hole Attachment sets

Attachment sets Self-adhesive labels to be used with magnets

Self-adhesive labels to be used with magnets Sensor foils

Sensor foils Neodymium self-sticking magnets, prisms, magnetized perpendicularly to the surface

Neodymium self-sticking magnets, prisms, magnetized perpendicularly to the surface Cheap magnets

Cheap magnets Magnetic attachment sets

Magnetic attachment sets Neodymium magnets, prisms with holes, magnetized perpendicularly to the surface

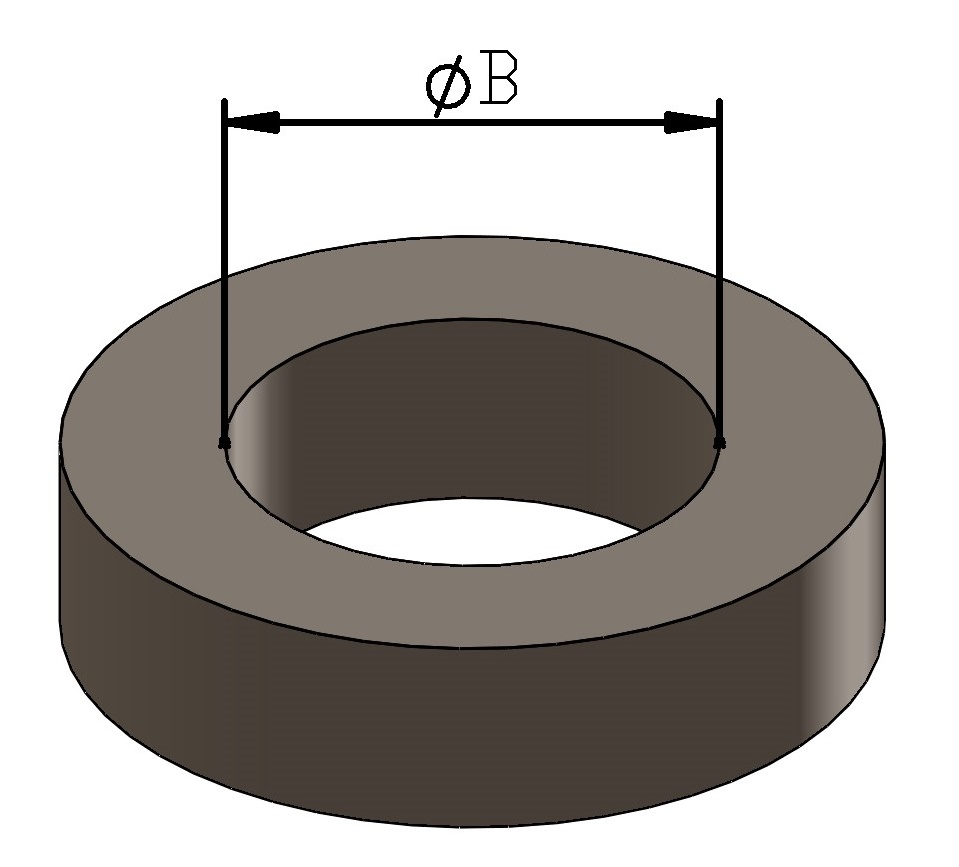

Neodymium magnets, prisms with holes, magnetized perpendicularly to the surface Neodymium magnets, rings, magnetized in parallel to the axis

Neodymium magnets, rings, magnetized in parallel to the axis Neodymium magnets, cylinders with screw hole, magnetized in parallel to the axis

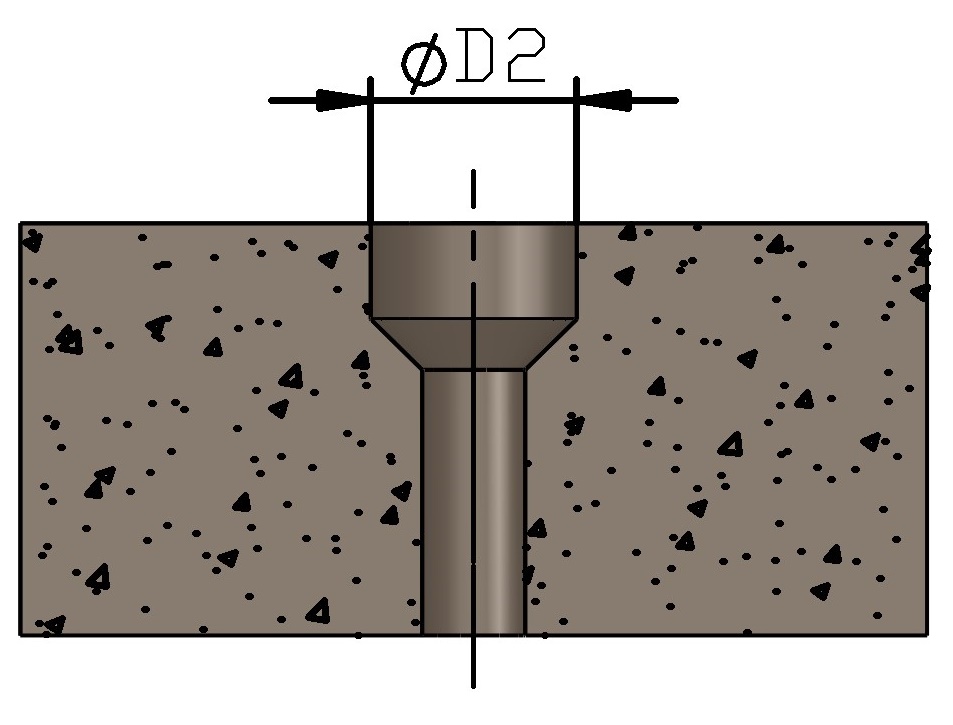

Neodymium magnets, cylinders with screw hole, magnetized in parallel to the axis Neodymium magnets, cylinders, magnetized perpendicularly to the axis

Neodymium magnets, cylinders, magnetized perpendicularly to the axis Neodymium magnets, cylinders, magnetized in parallel to the axis

Neodymium magnets, cylinders, magnetized in parallel to the axis Atypical neodymium magnets

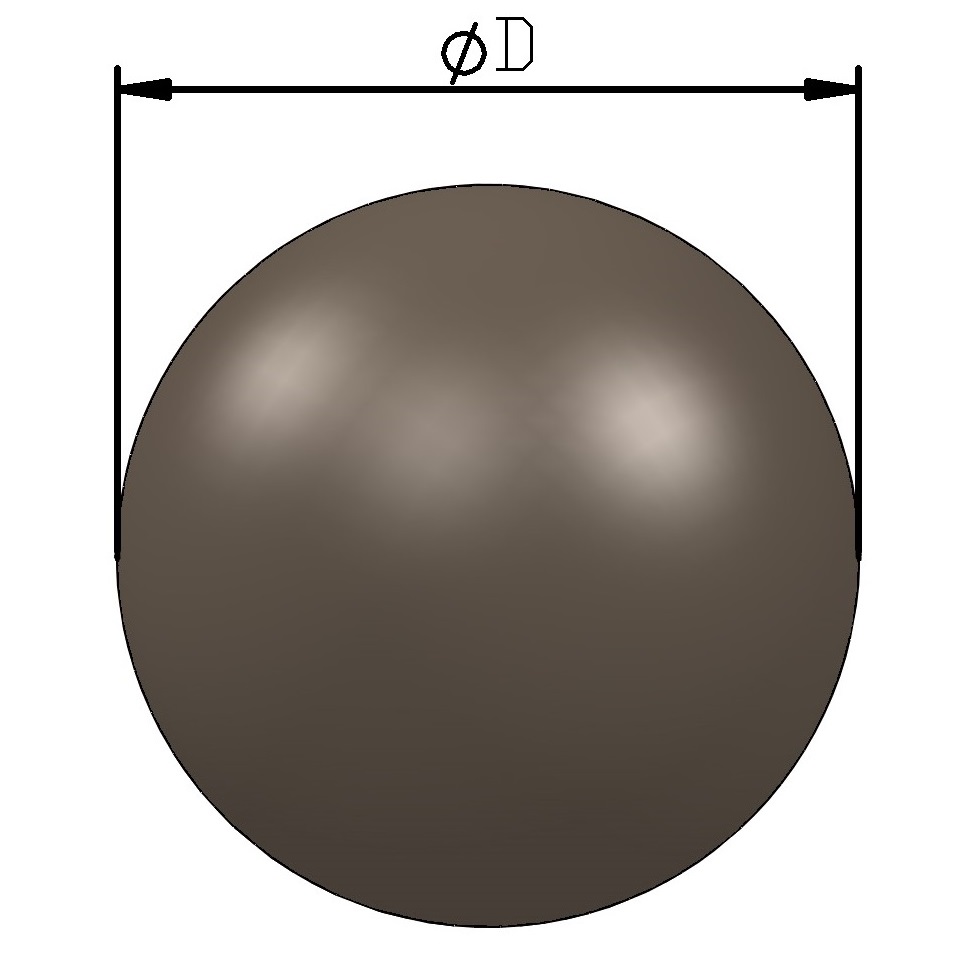

Atypical neodymium magnets Magnetic balls

Magnetic balls Neodymium magnets, segments, magnetized perpendicularly to the surface

Neodymium magnets, segments, magnetized perpendicularly to the surface Neodymium magnets, rings, magnetized perpendicularly to the axis

Neodymium magnets, rings, magnetized perpendicularly to the axis Neodymium magnets, prisms, magnetized perpendicularly to the surface

Neodymium magnets, prisms, magnetized perpendicularly to the surface Neodymium magnets, prisms, magnetized in the longitudinal direction

Neodymium magnets, prisms, magnetized in the longitudinal direction Board magnets

Board magnets Baby fridge magnets

Baby fridge magnets Wooden magnets

Wooden magnets Animal magnets

Animal magnets Fridge magnets

Fridge magnets Photo magnets

Photo magnets Magnetic separators for kaolin

Magnetic separators for kaolin Magnetic pellet separators

Magnetic pellet separators Magnetic separators for wood chips

Magnetic separators for wood chips Magnetic separators on soot

Magnetic separators on soot Magnetic flour separators

Magnetic flour separators Magnetic separators for plastic granules

Magnetic separators for plastic granules Magnetic sugar crystal separators

Magnetic sugar crystal separators Magnetic separators for powdered sugar

Magnetic separators for powdered sugar Magnetic separators for ceramic material

Magnetic separators for ceramic material Magnetic separators for rinsing baths

Magnetic separators for rinsing baths Magnetic separators for cooling oil

Magnetic separators for cooling oil Magnetic separators for sugar juice

Magnetic separators for sugar juice Magnetic glaze separators

Magnetic glaze separators Magnetic pate separators

Magnetic pate separators Magnetic ketchup separators

Magnetic ketchup separators Magnetic yogurt separators

Magnetic yogurt separators Magnetic oil separators

Magnetic oil separators Magnetic separators for cooling emulsion

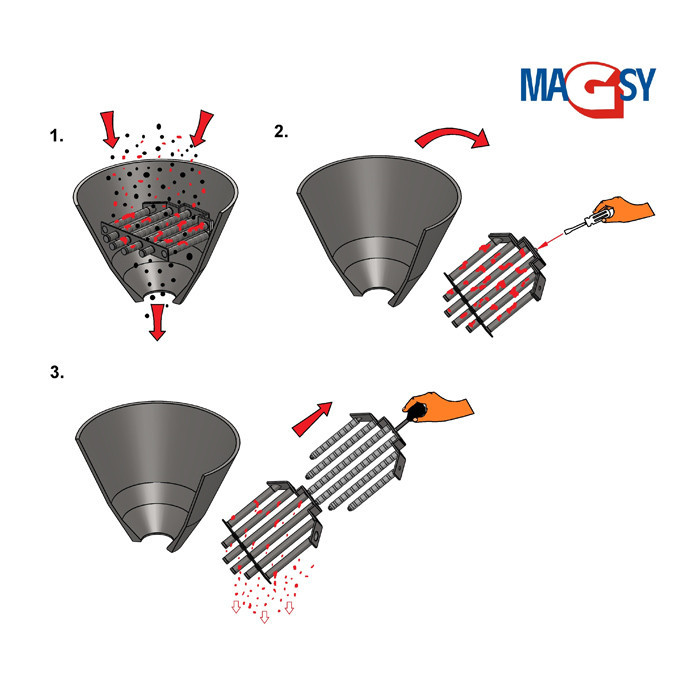

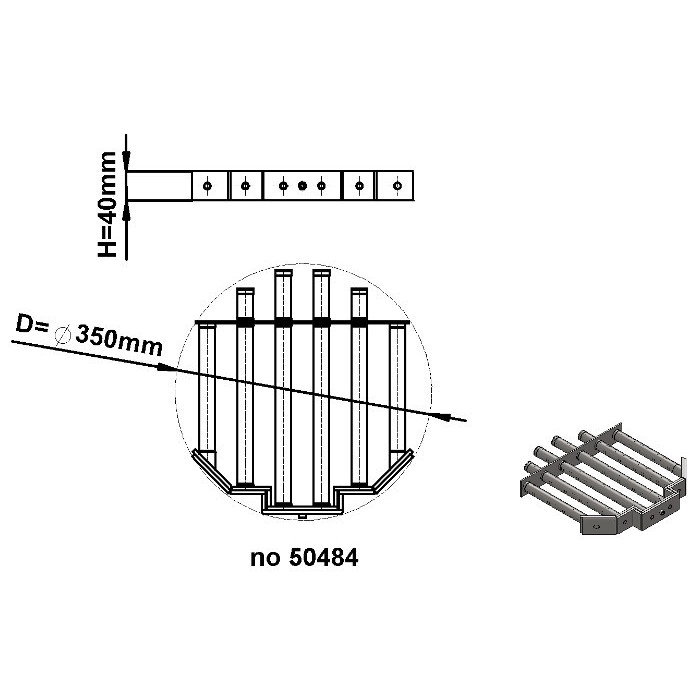

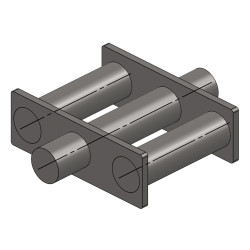

Magnetic separators for cooling emulsion Magnetic grids, finger magnets

Magnetic grids, finger magnets Magnets for injection moulding machine hoppers

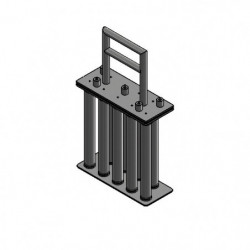

Magnets for injection moulding machine hoppers Magnetic rods

Magnetic rods Separation vessels

Separation vessels Rotational magnetic separators

Rotational magnetic separators Plate magnetic separator

Plate magnetic separator Telescopic magnetic separators - with automatic cleaning

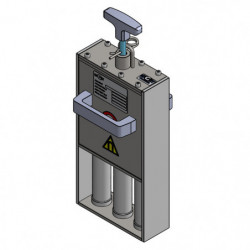

Telescopic magnetic separators - with automatic cleaning Telescopic magnetic separators - with manual cleaning

Telescopic magnetic separators - with manual cleaning Magnetic testing rods

Magnetic testing rods Magnetic drums

Magnetic drums Flow magnetic separators

Flow magnetic separators Magnetic plates

Magnetic plates Yeckel 50x50x3 mm

Yeckel 50x50x3 mm Yeckel 25x15x1,5 mm

Yeckel 25x15x1,5 mm Yeckel 25x25x2 mm

Yeckel 25x25x2 mm Yeckel 30x20x2 mm

Yeckel 30x20x2 mm Yeckel 30x30x3 mm

Yeckel 30x30x3 mm Yeckel 30x30x2 mm

Yeckel 30x30x2 mm Yeckel 40x40x2 mm

Yeckel 40x40x2 mm Yeckel 50x20x2 mm

Yeckel 50x20x2 mm Yeckel 60x60x4 mm

Yeckel 60x60x4 mm Yeckel 70x70x2 mm

Yeckel 70x70x2 mm Yeckel 60x40x4 mm

Yeckel 60x40x4 mm Yeckel 60x60x2 mm

Yeckel 60x60x2 mm Yeckel 100x100x3 mm

Yeckel 100x100x3 mm Yeckel 120x80x3 mm

Yeckel 120x80x3 mm Yeckel 200x100x3 mm

Yeckel 200x100x3 mm Yeckel 20x20x2 mm

Yeckel 20x20x2 mm Stainless steel L profile 40x40x4 mm

Stainless steel L profile 40x40x4 mm Stainless steel L profile 30x30x3 mm

Stainless steel L profile 30x30x3 mm Stainless steel L profile 25x25x3 mm

Stainless steel L profile 25x25x3 mm Stainless steel L profile 20x20x3 mm

Stainless steel L profile 20x20x3 mm Stainless steel L profile 20x10x3 mm

Stainless steel L profile 20x10x3 mm Stainless steel rods 20 mm

Stainless steel rods 20 mm Stainless steel rods 25 mm

Stainless steel rods 25 mm Stainless steel rods 28 mm

Stainless steel rods 28 mm Stainless steel rods 30 mm

Stainless steel rods 30 mm Stainless steel rods 3 mm

Stainless steel rods 3 mm Stainless steel rods 12 mm

Stainless steel rods 12 mm Stainless steel rods 9 mm

Stainless steel rods 9 mm Stainless steel rods 10 mm

Stainless steel rods 10 mm Stainless steel rods 8 mm

Stainless steel rods 8 mm Stainless steel rods 6 mm

Stainless steel rods 6 mm Stainless steel rods 5 mm

Stainless steel rods 5 mm Stainless steel rods 4 mm

Stainless steel rods 4 mm Stainless steel rods 18 mm

Stainless steel rods 18 mm Stainless steel rods 100 mm

Stainless steel rods 100 mm Stainless steel rods 14 mm

Stainless steel rods 14 mm Stainless steel rods 32 mm

Stainless steel rods 32 mm Stainless steel rods 35 mm

Stainless steel rods 35 mm Stainless steel rods 36 mm

Stainless steel rods 36 mm Stainless steel rods 40 mm

Stainless steel rods 40 mm Stainless steel rods 45 mm

Stainless steel rods 45 mm Stainless steel rods 50 mm

Stainless steel rods 50 mm Stainless steel rods 55 mm

Stainless steel rods 55 mm Stainless steel rods 60 mm

Stainless steel rods 60 mm Stainless steel rods 70 mm

Stainless steel rods 70 mm Brushed pipes

Brushed pipes Welded pipes

Welded pipes Seamless pipes

Seamless pipes